The immersive egg

Laser cutting, 3D-printing, woodworking

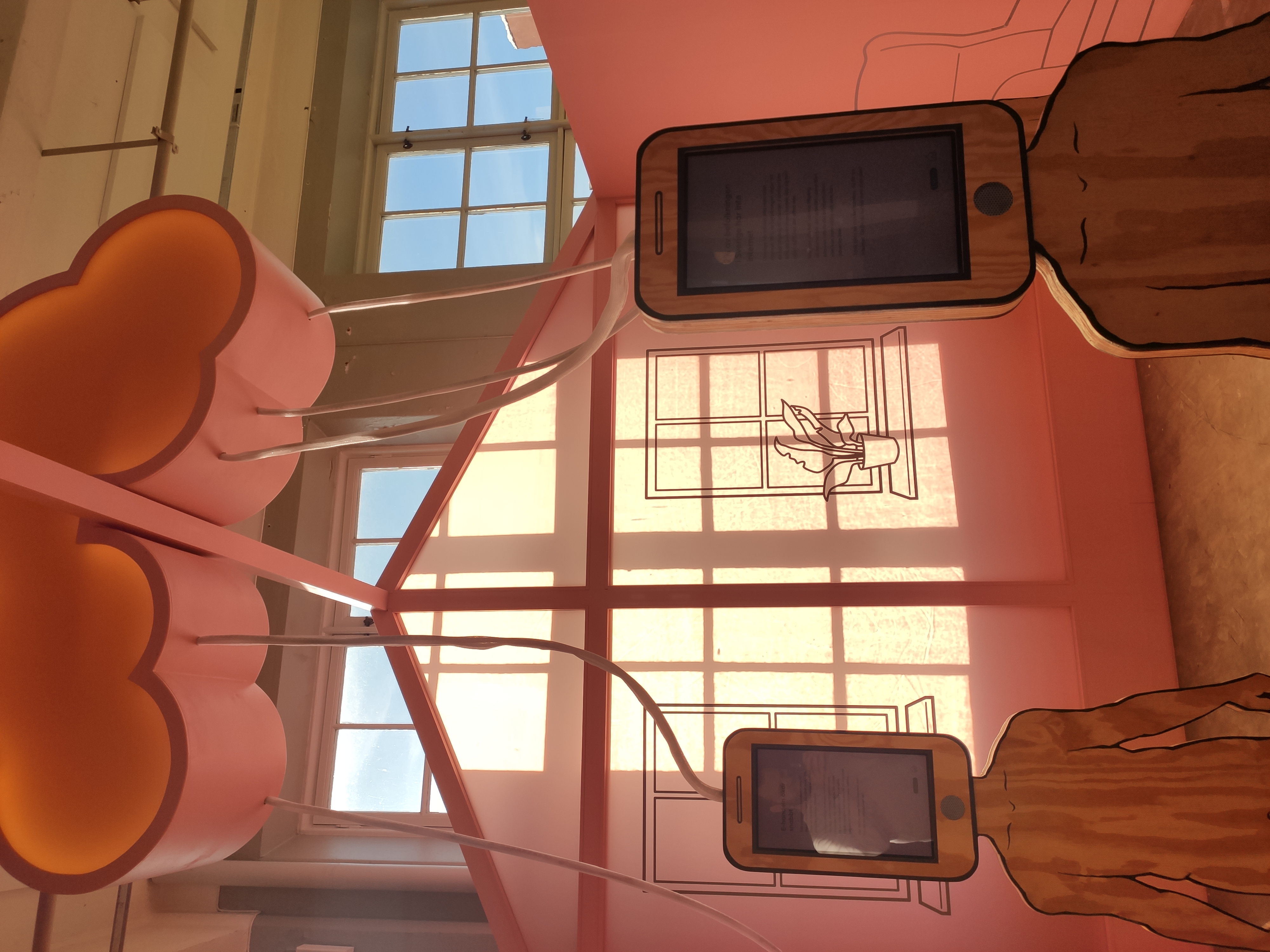

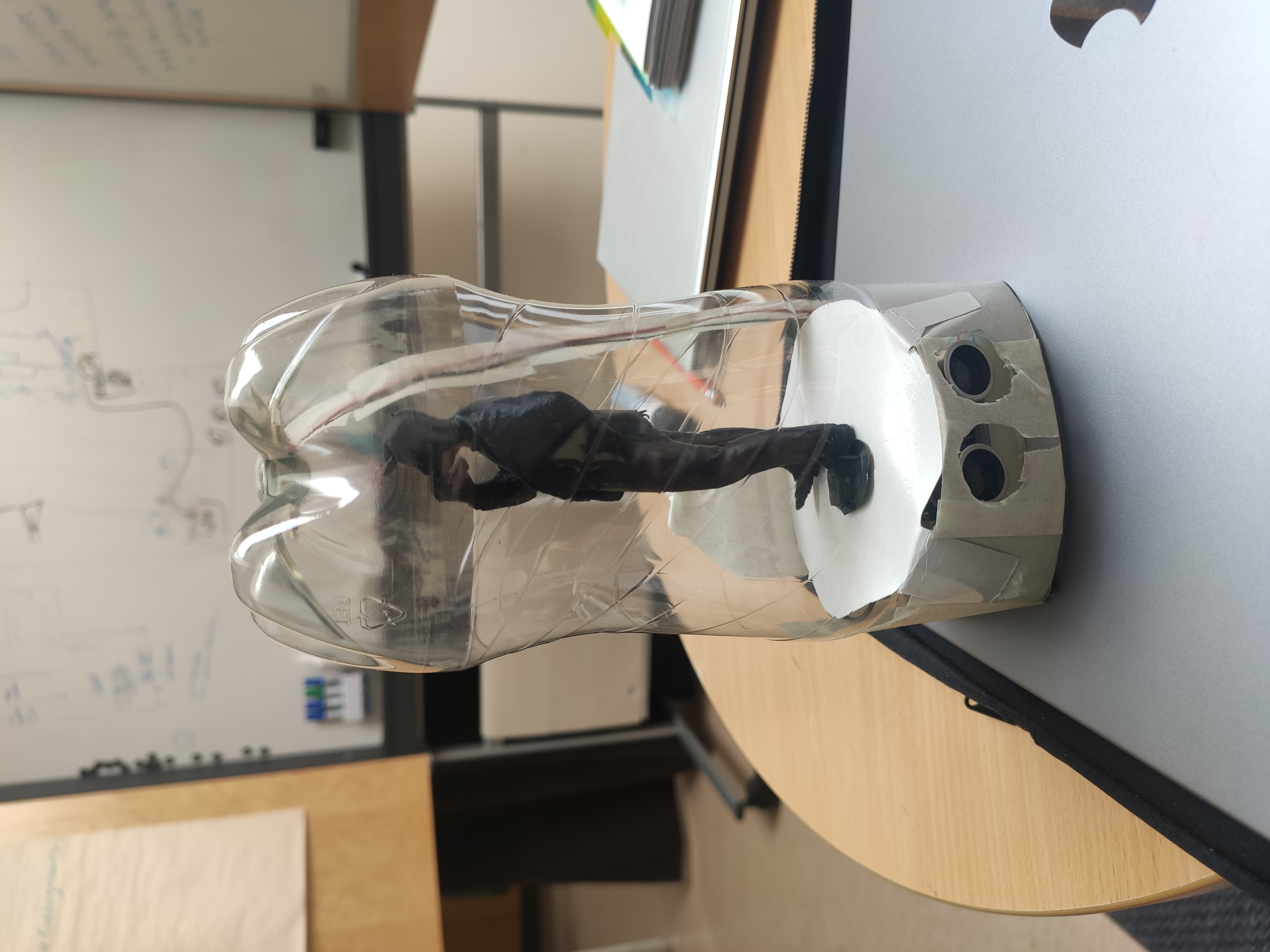

The Immersive Egg takes its inspiration from two places. One is Eero Aarnio’s “Ball Chair Audio”, where the classic ball chair is turned into an isolated listening space with built-in speakers, letting you create a focused audio experience without disturbing the room outside. The other inspiration comes from modern dome cinemas, where moving images fill your whole field of view and the sound surrounds you completely. The Egg Chair is a mix of these two ideas; a full scale dome experience but in the shape of a single chair.

One of the biggest challenges when working with sound in exhibition environments is sound leakage. Ball Chair Audio solves this on a stereo level by isolating the listener, without disturbing the room around it. Combined with the idea of dome cinemas filling the viewer’s whole field of vision, the Immersive Egg merges these two approaches into one compact concept.

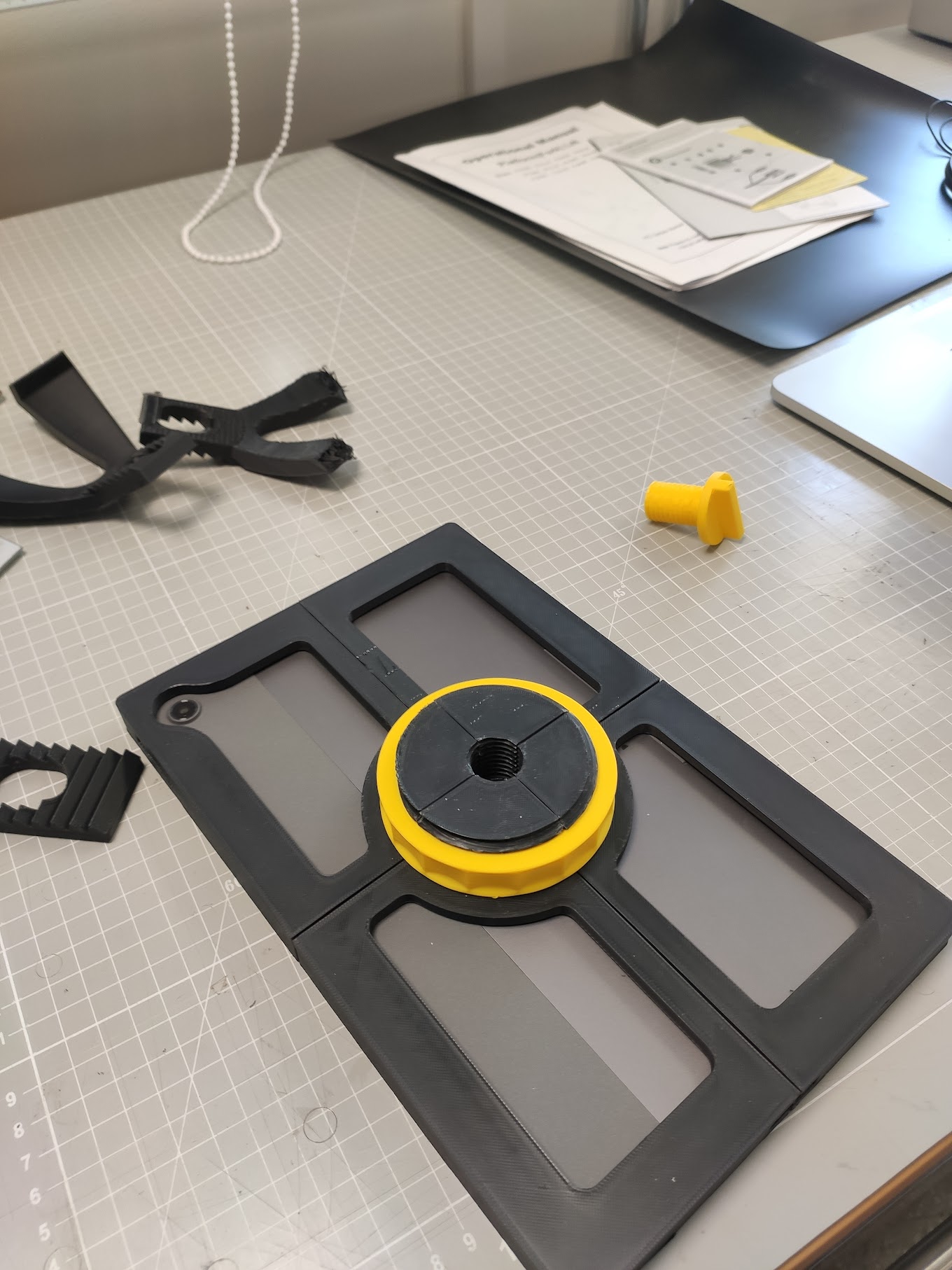

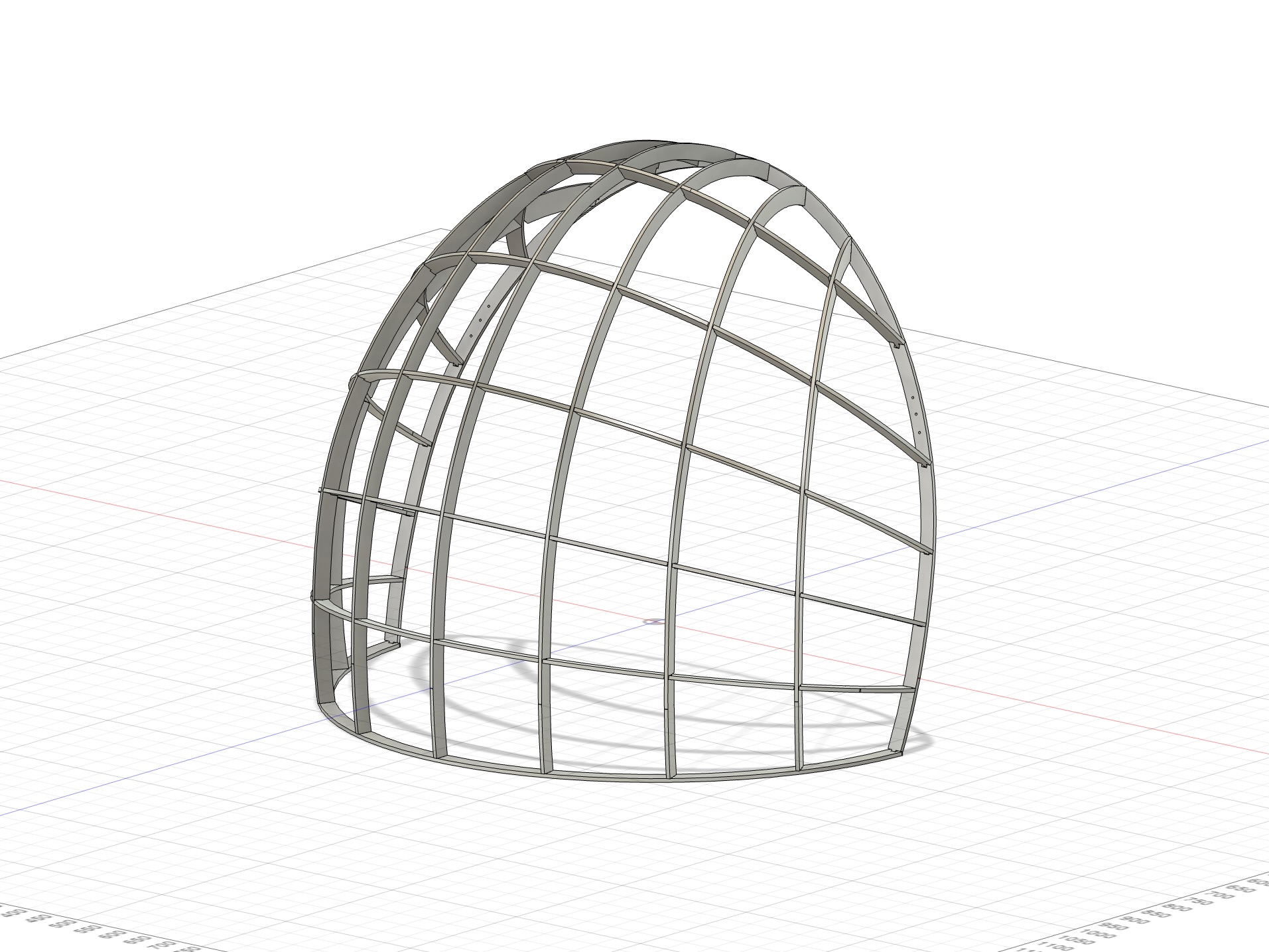

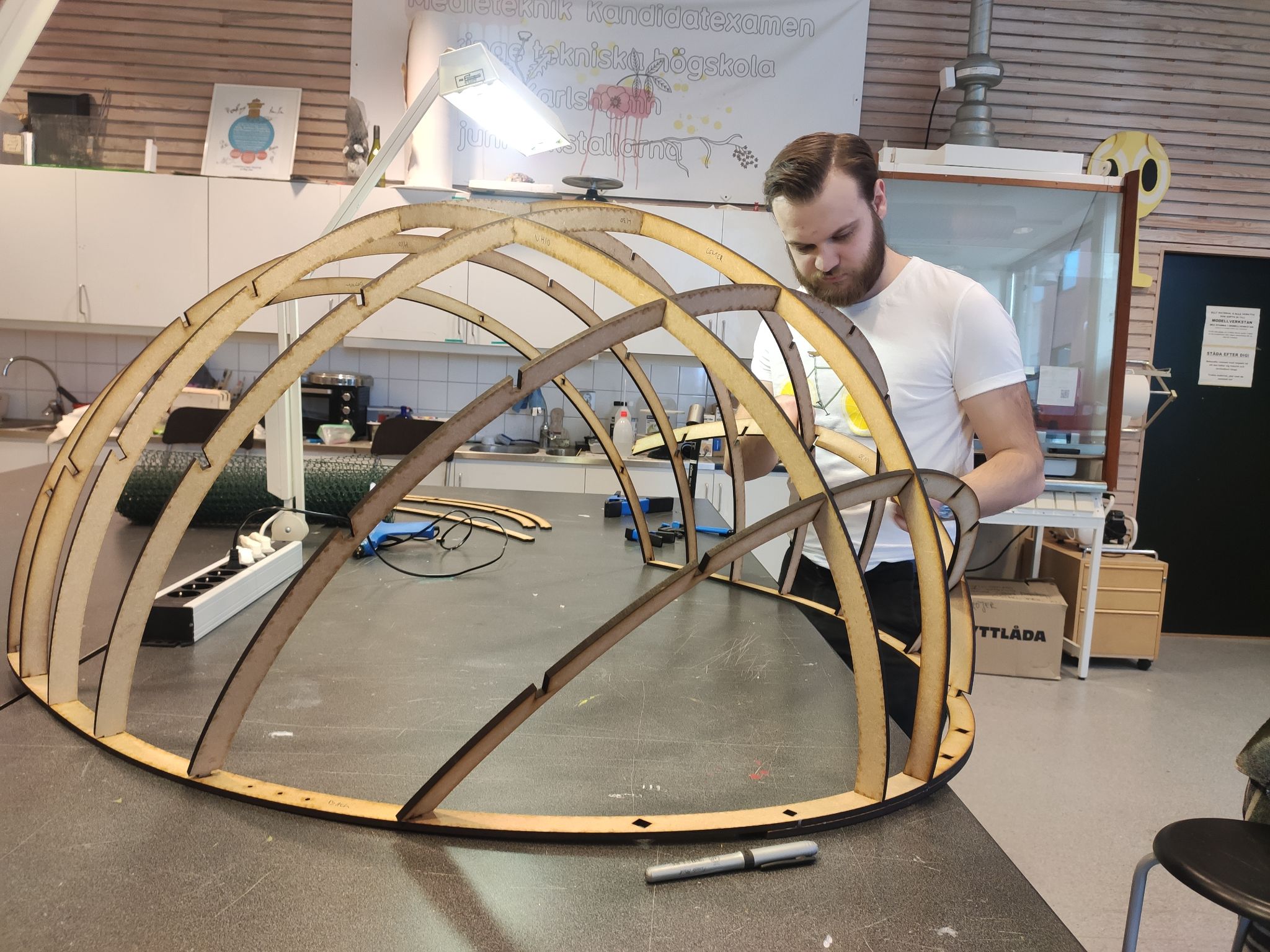

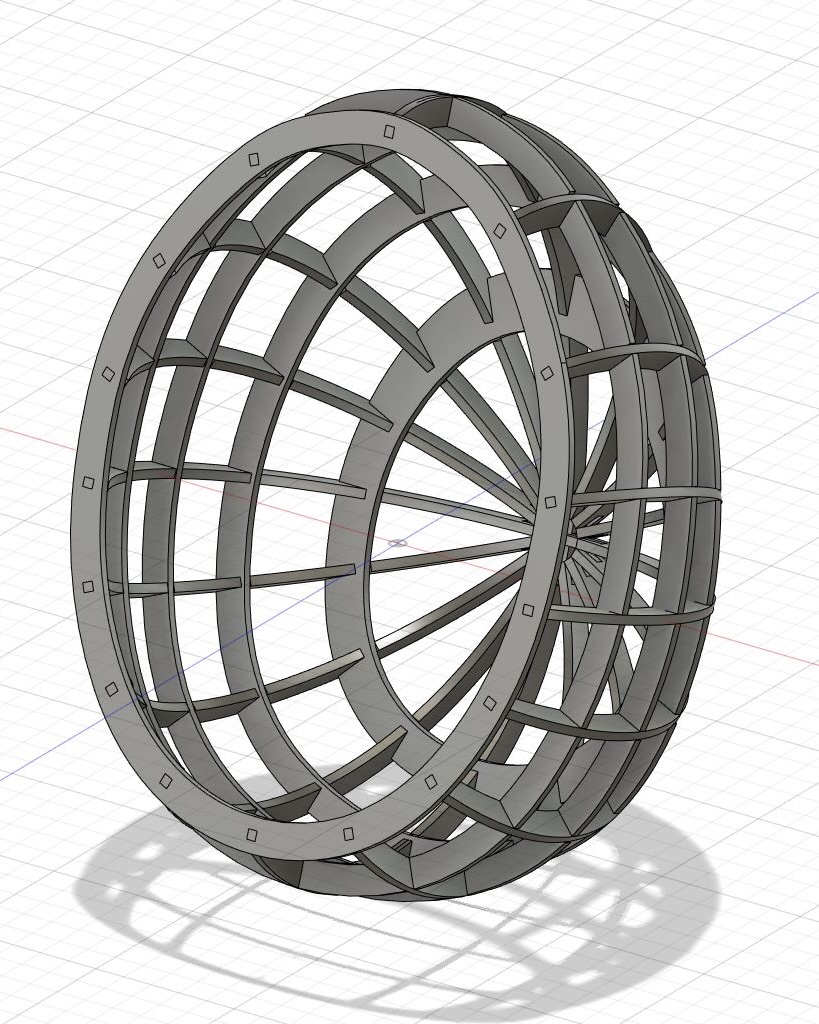

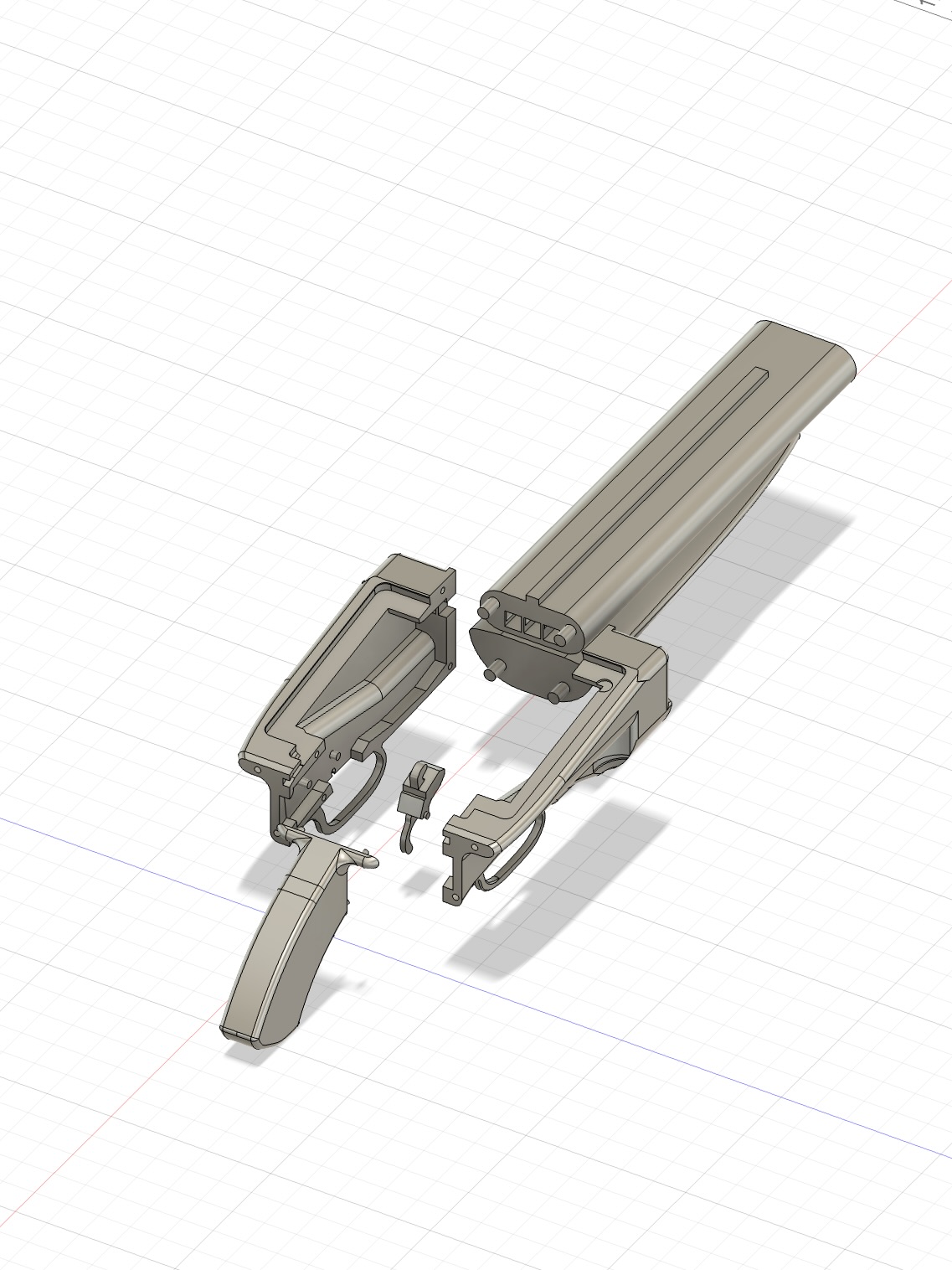

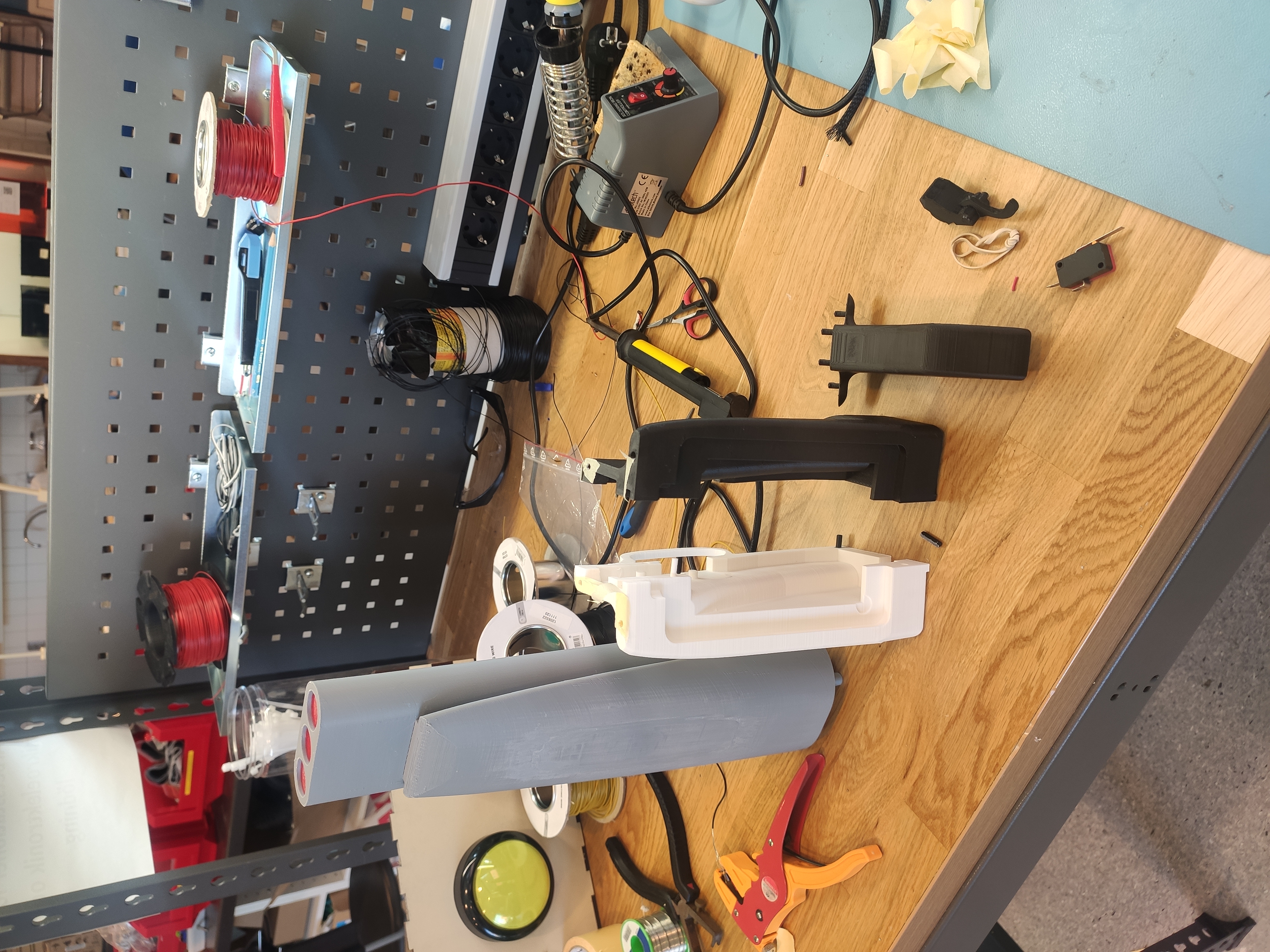

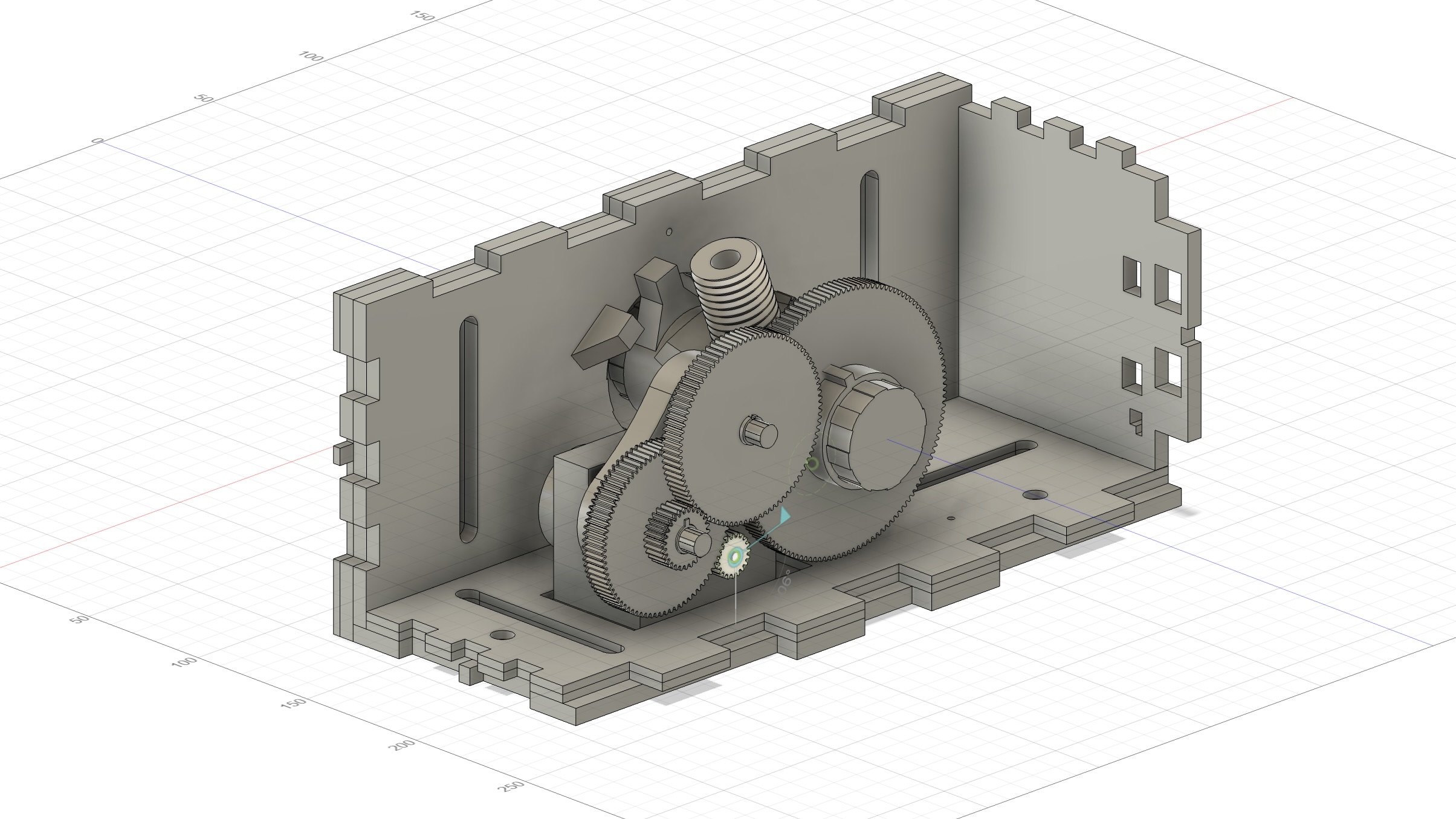

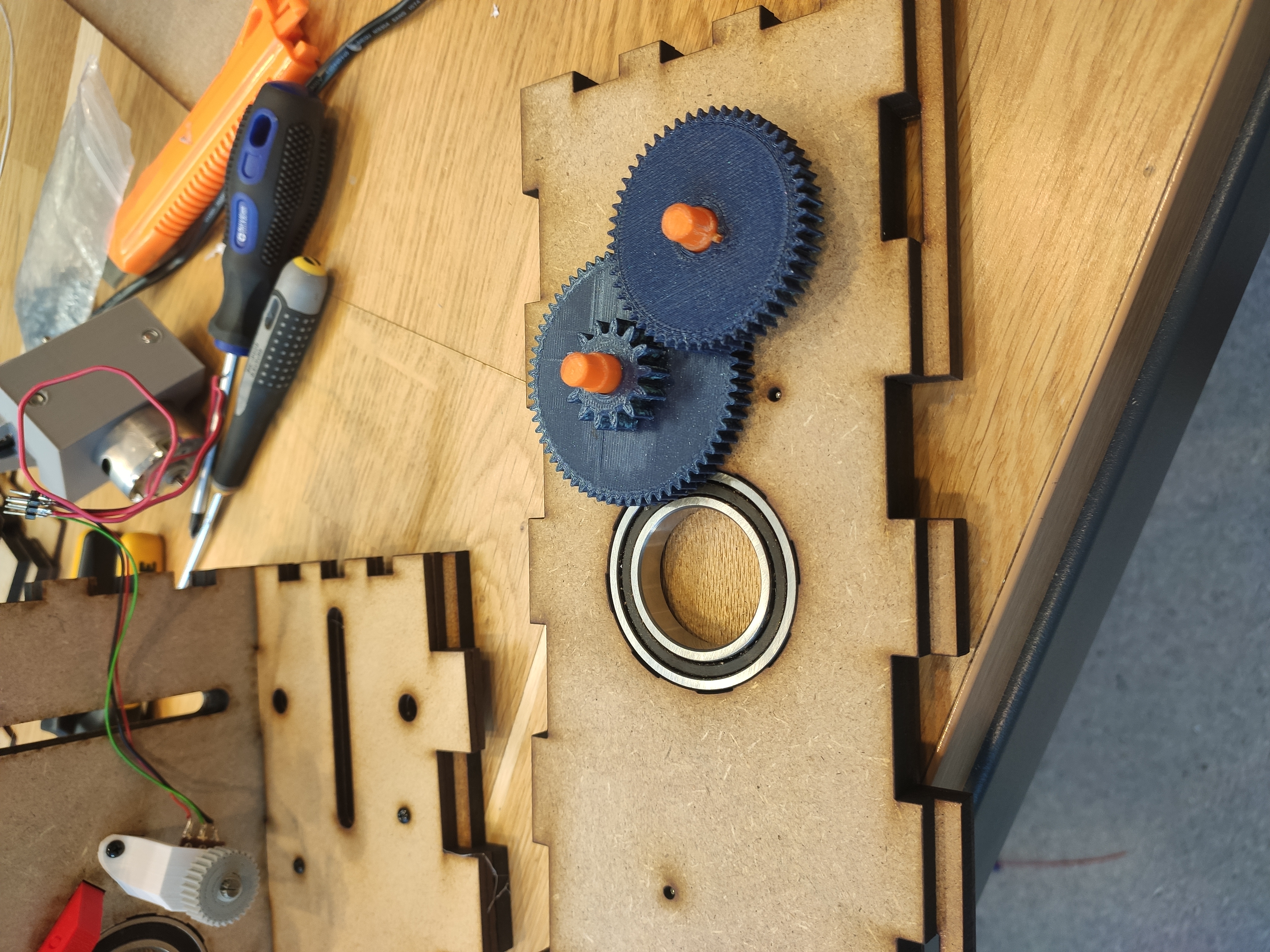

The curved screen was one of the most complex shapes in the whole project, but designing it in CAD made it possible to build. Once the frame was laser-cut, I could assemble the skeleton and start testing the form in full scale, which early on helped reveal how unforgiving the dome is for projection mapping.

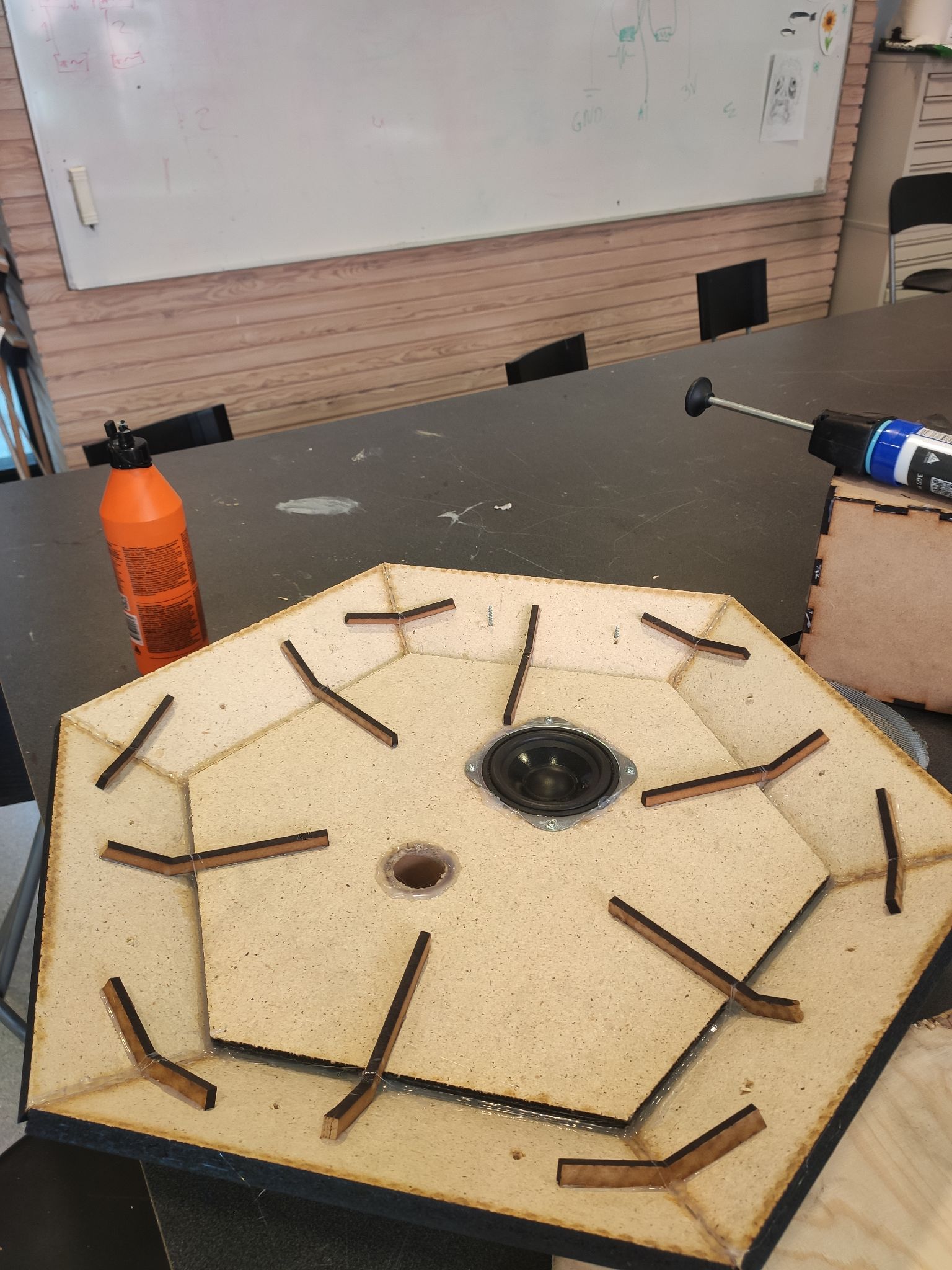

The chair structure needed to be strong, stable and comfortable, which required both mechanical planning in CAD and hands-on craftsmanship in the workshop. Working with thicker plywood gave more freedom for shaping and ergonomics.

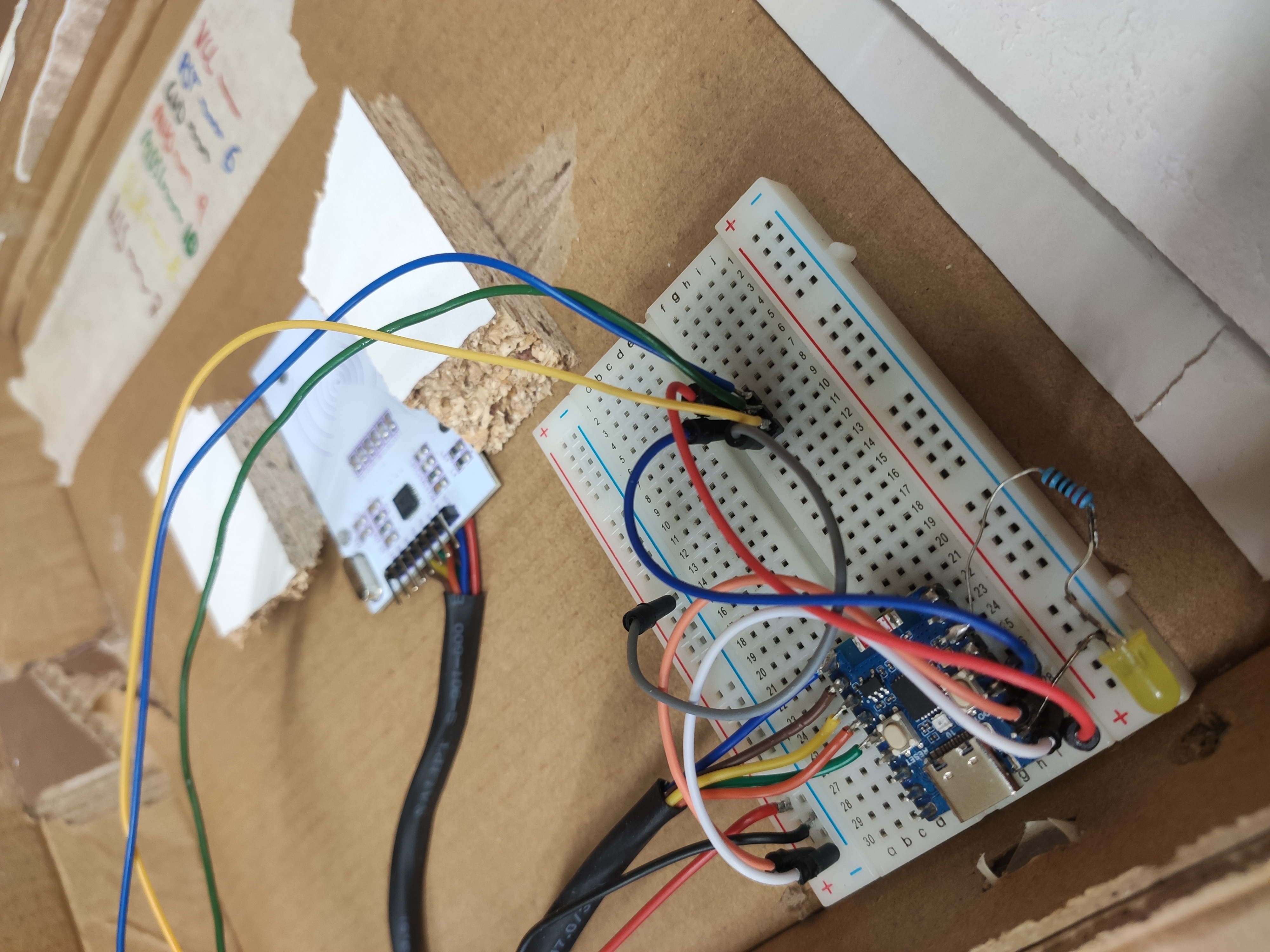

The limited space inside the chair made the audio design difficult, especially the subwoofer. I built a custom dual-chamber subwoofer that works both as a seat and subwoofer, which gave a strong low-end experience considering the small volume. This part of the project connected woodworking, CAD and sound design in a very practical way.

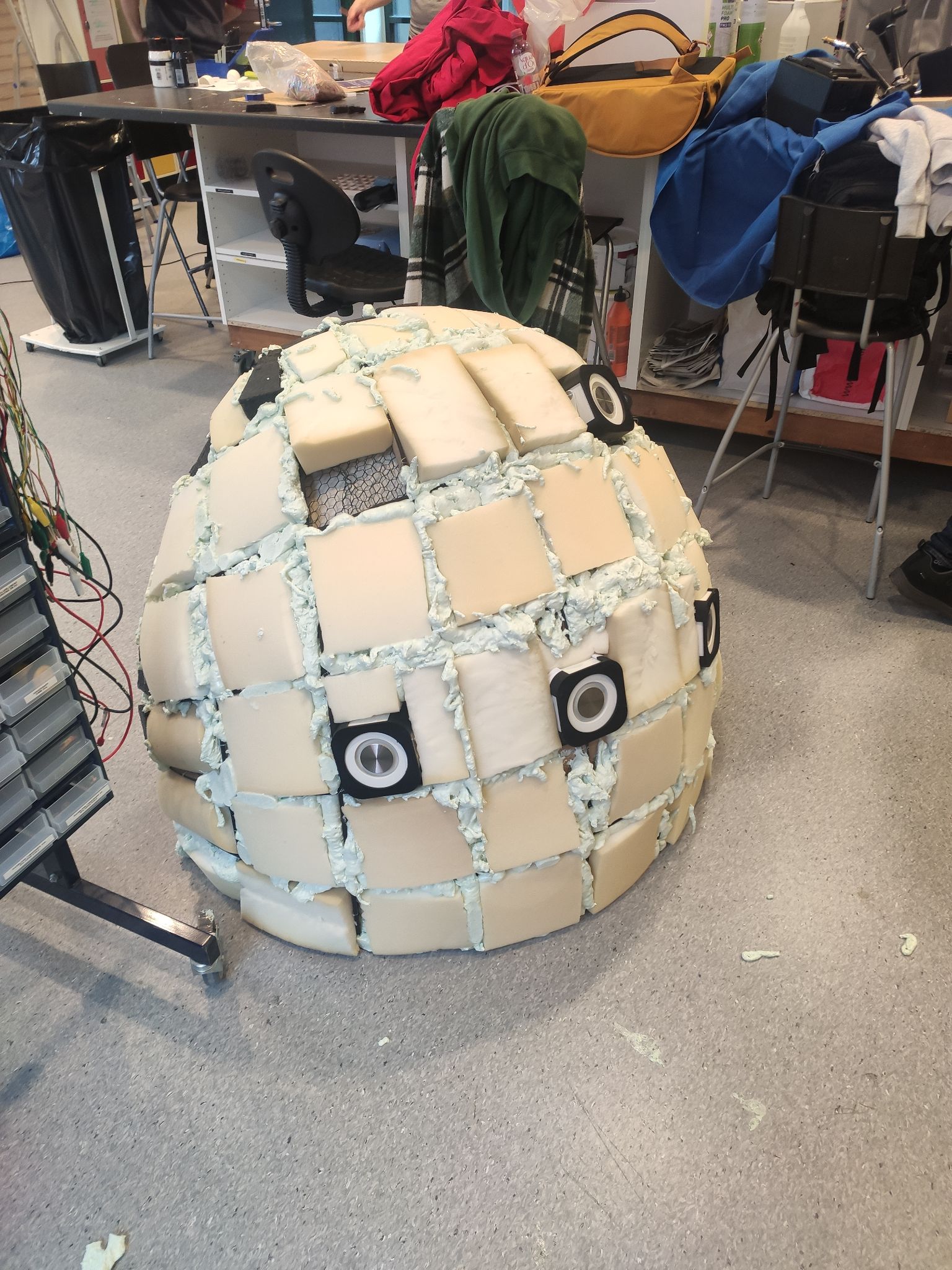

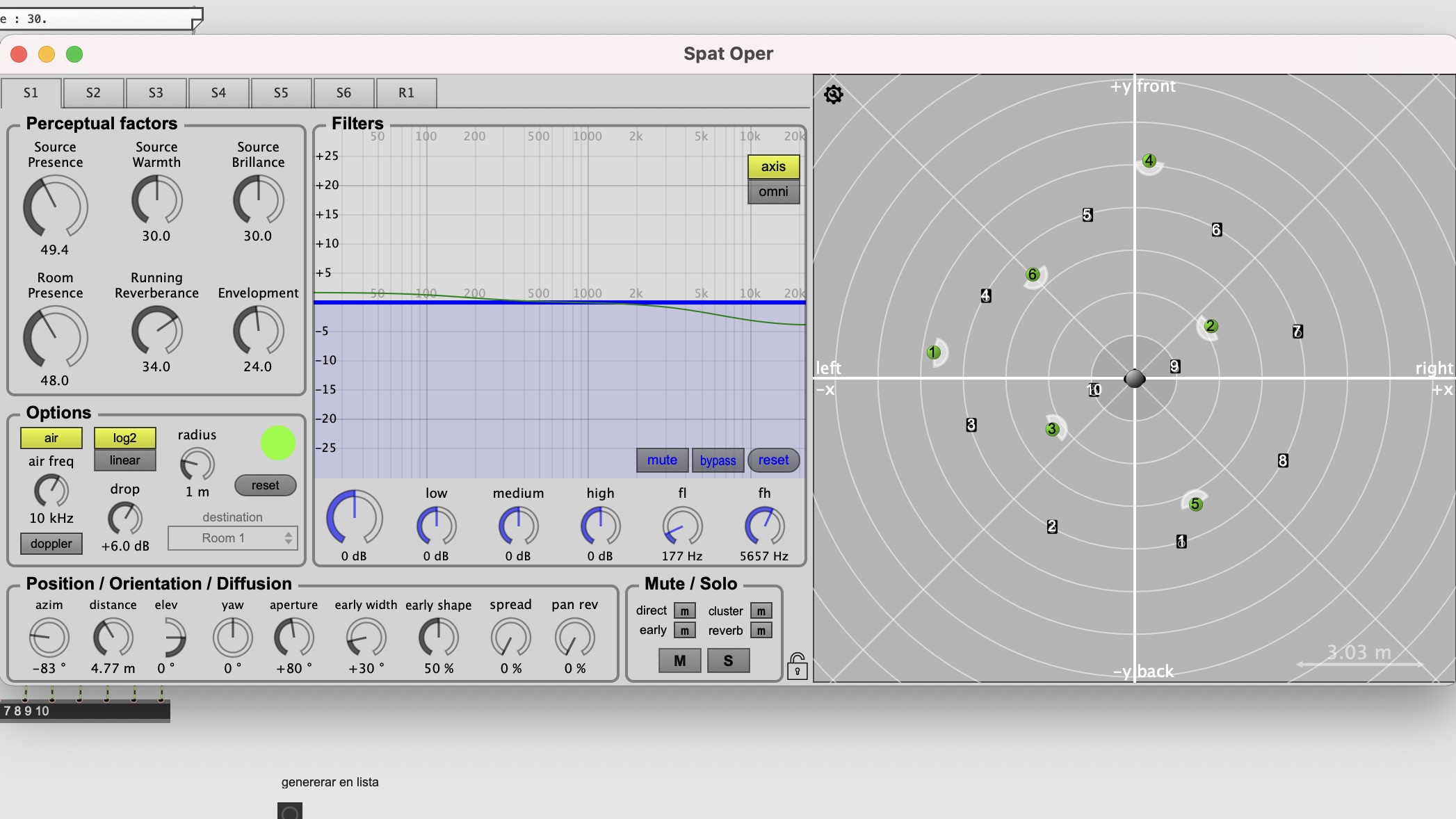

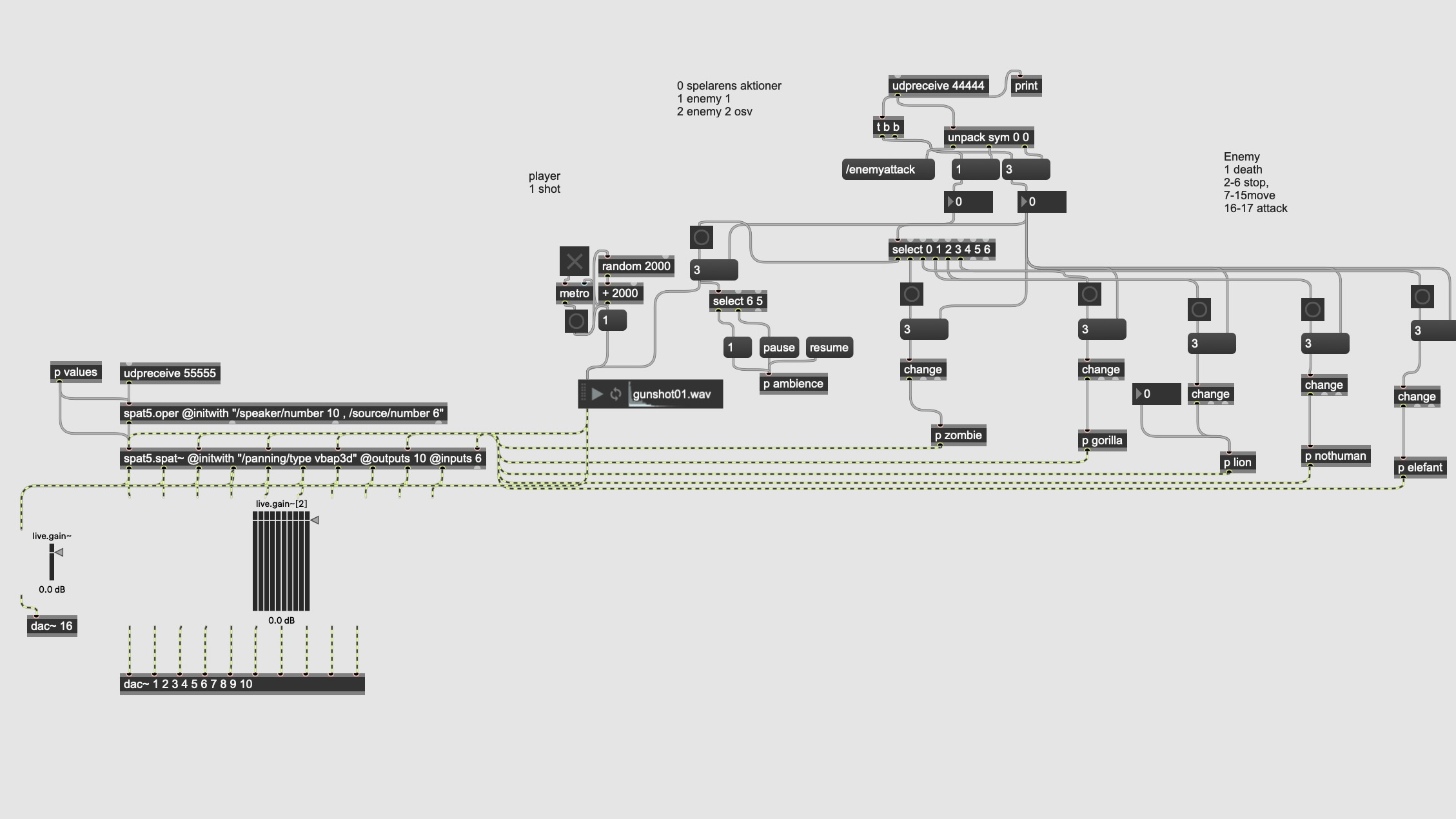

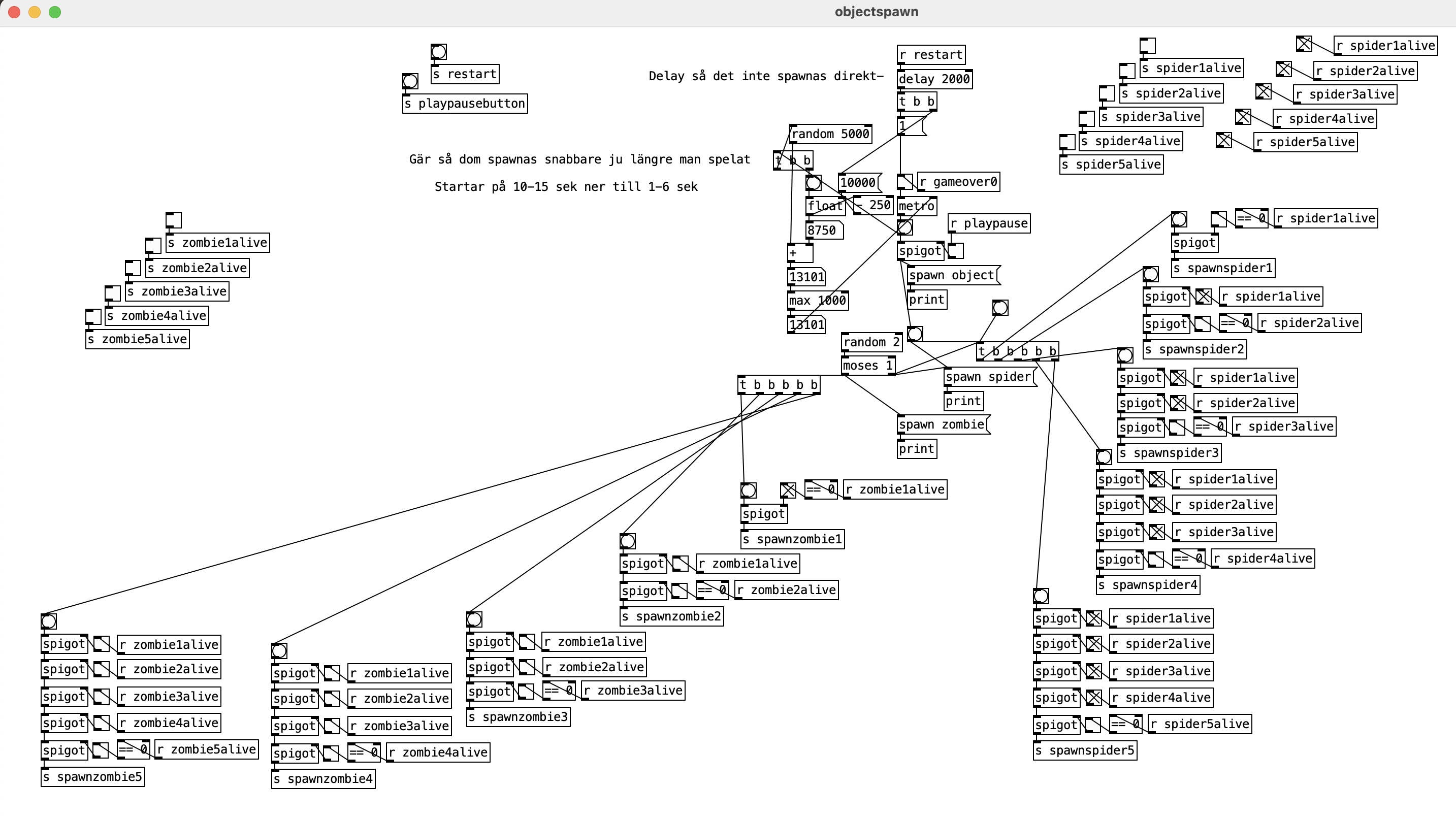

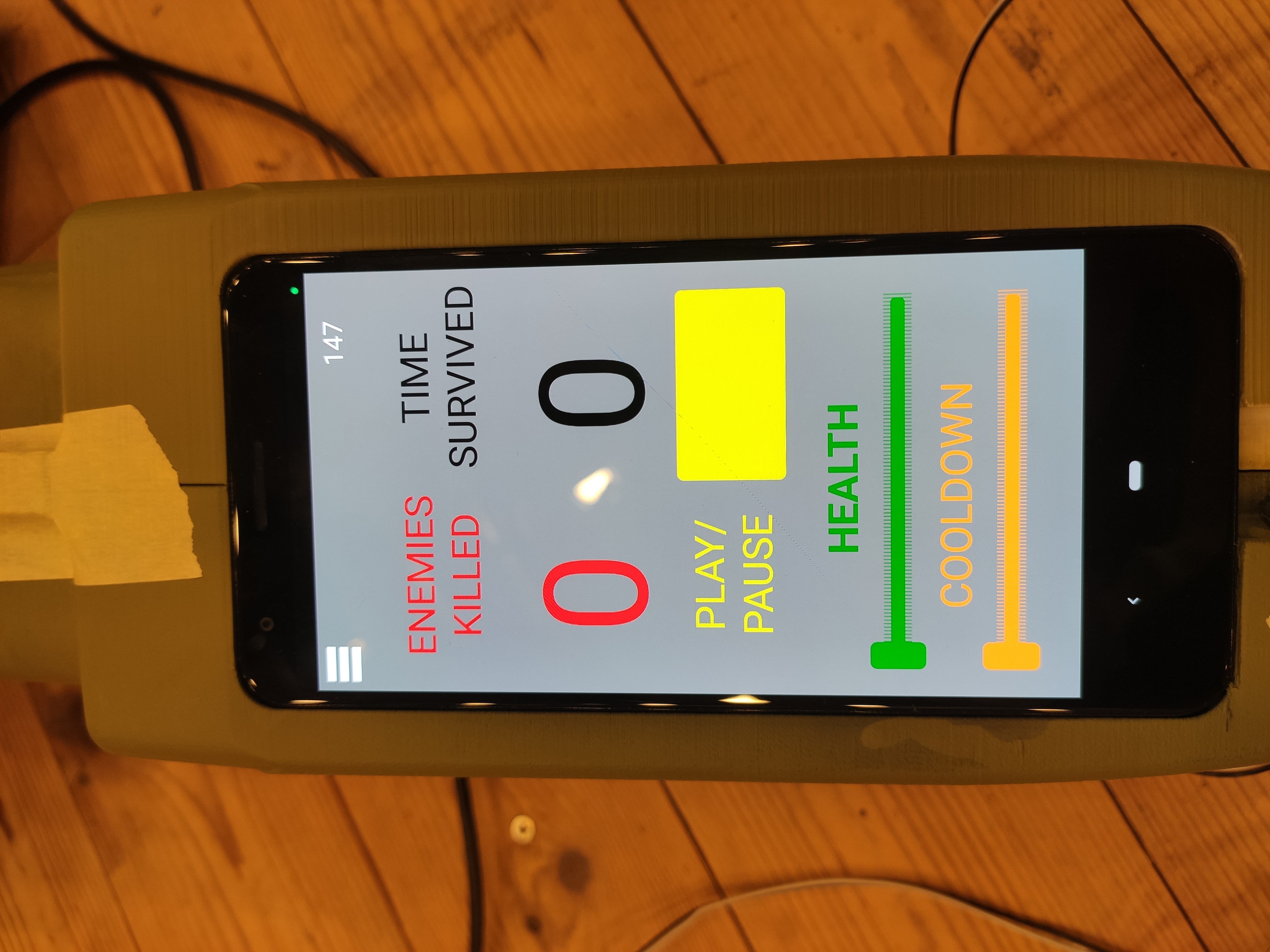

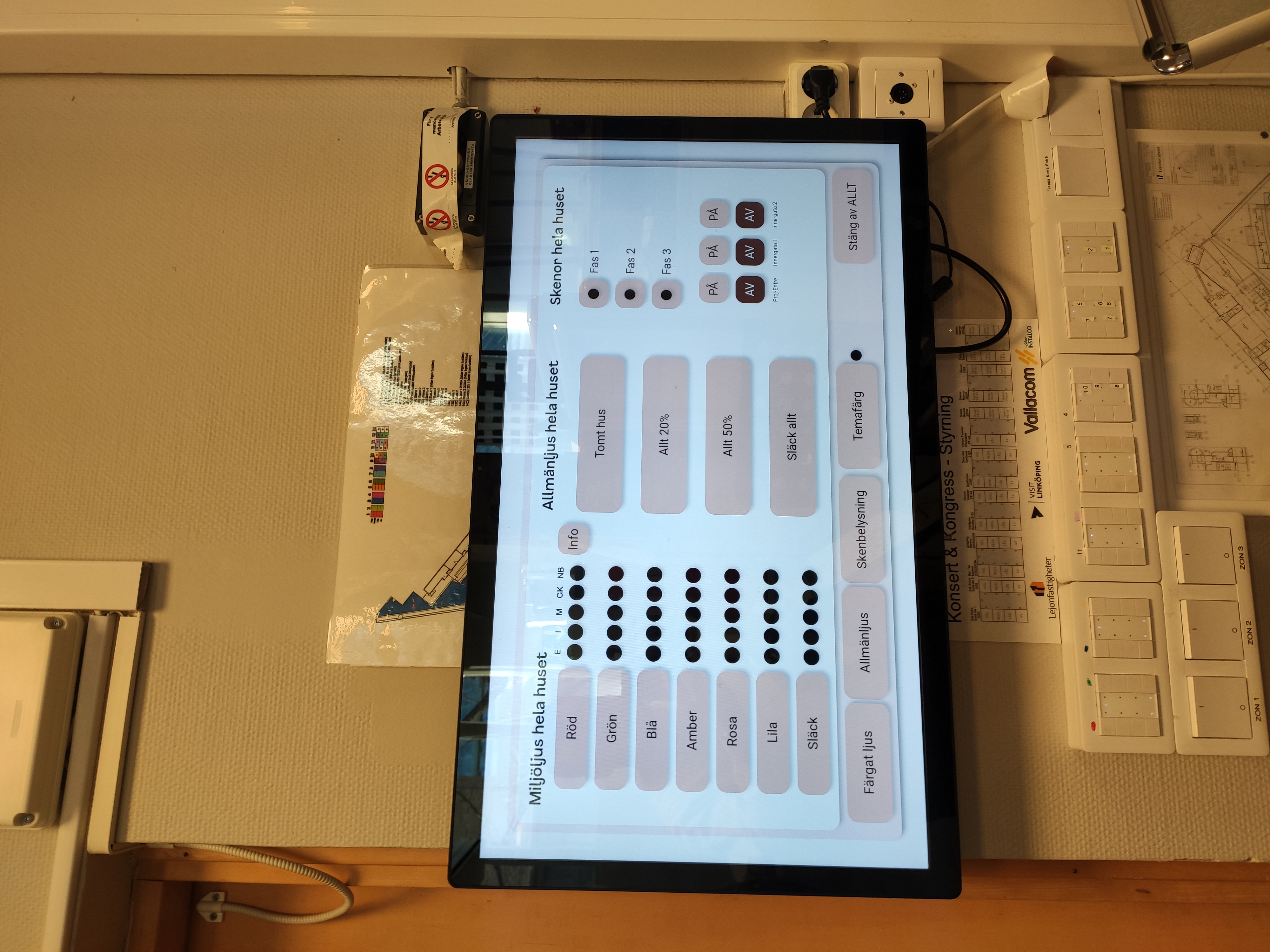

The 7.1.4 setup was placed around the user to create full spatial coverage, with Dolby Atmos standard placements. Soft foam and spray insulation were used as a first proof-of-concept for isolating sound from outside and preventing sound leakage. It worked well enough for testing, but higher-quality materials would make a major difference in a final version.

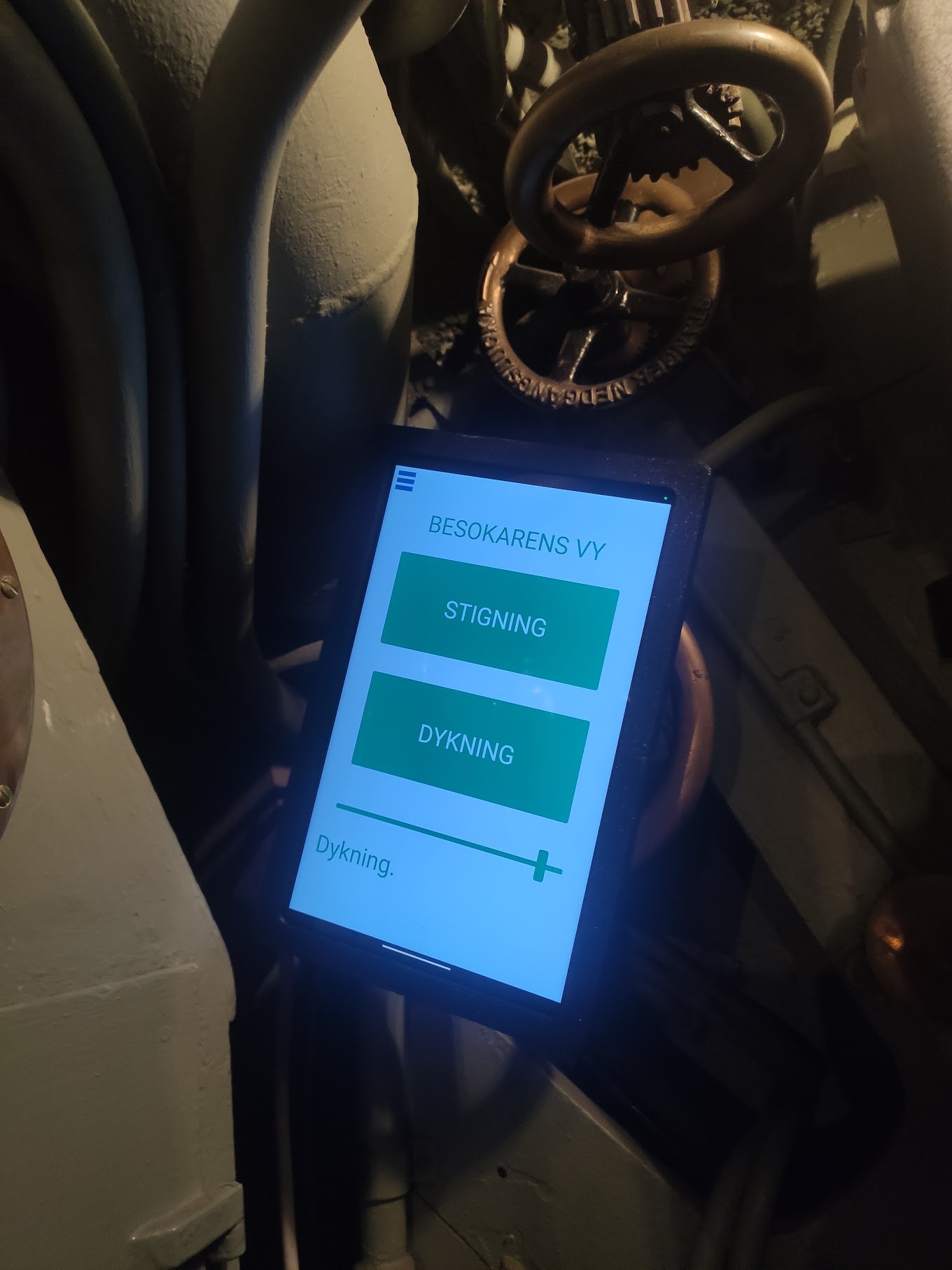

The projection system became one of the hardest parts of the build. We tested different setups; from a small internal projector to a bigger projector mounted outside using a curved mirror, but none of them were stable enough or gave a large enough image. The best result came from two external projectors crossing their images over each shoulder, which worked with the opening screen and gave a usable picture. The projection mapping on the curved surface was still tricky, and good enough for a proof of concept, but not for a final product.

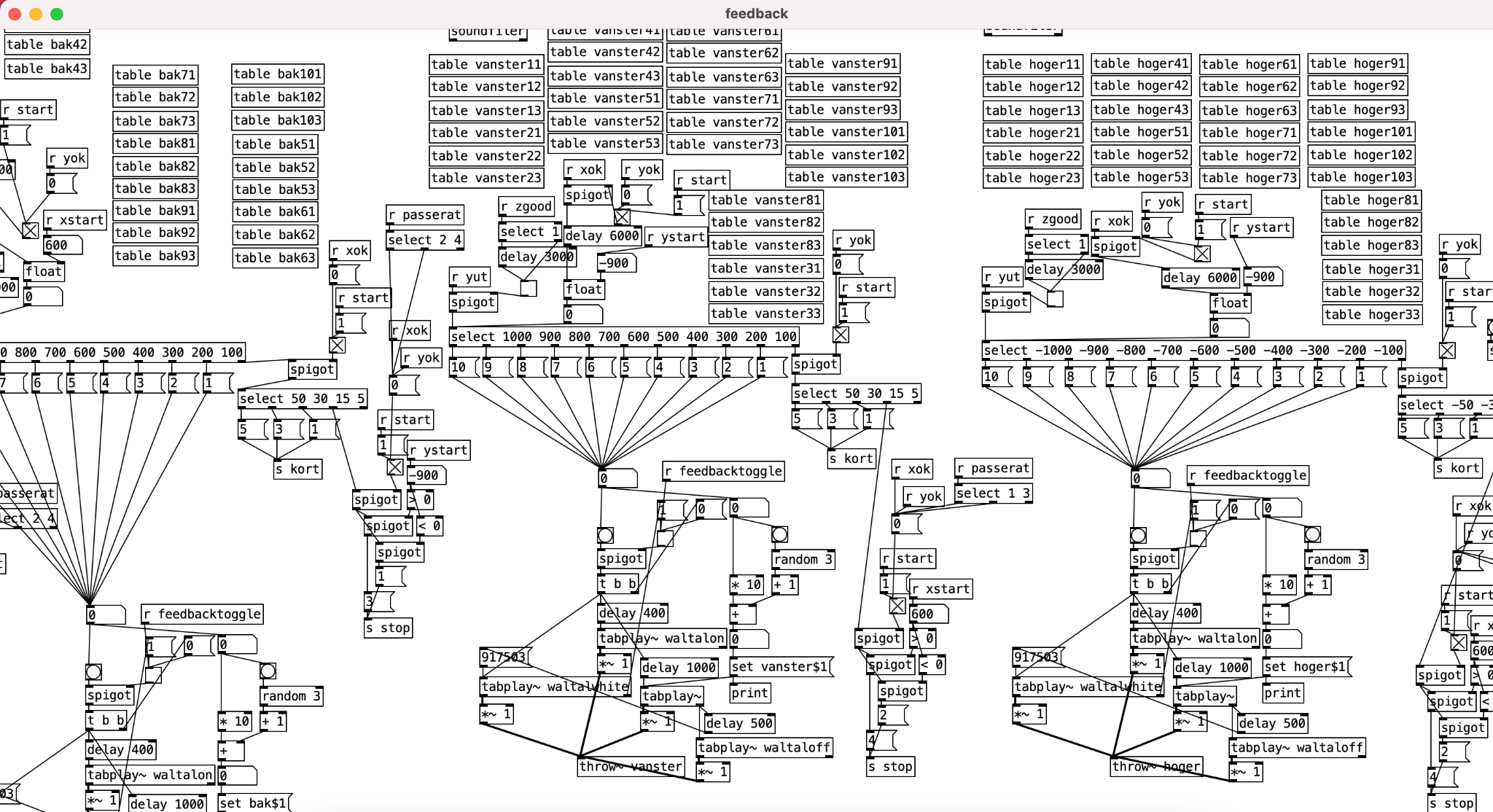

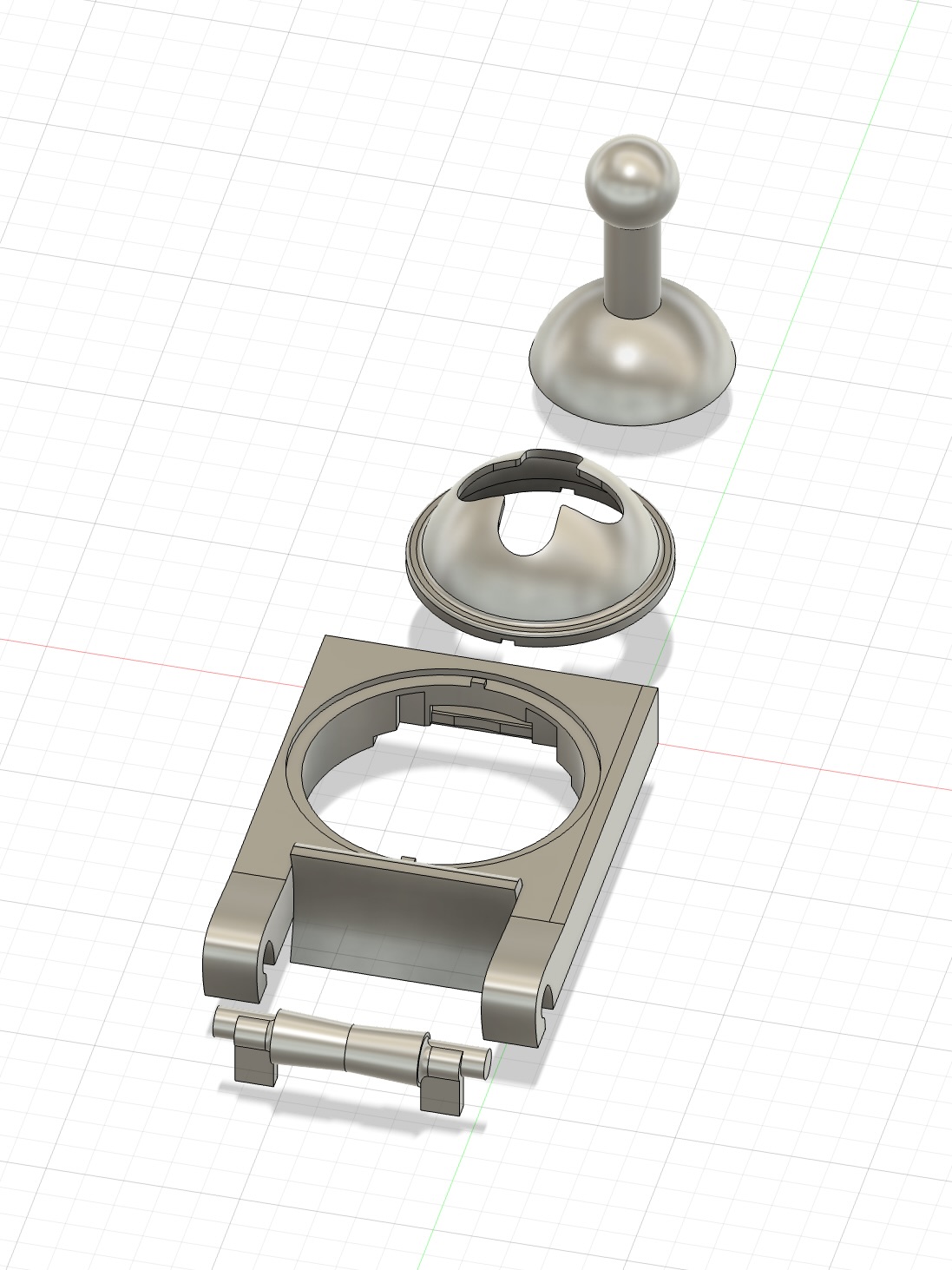

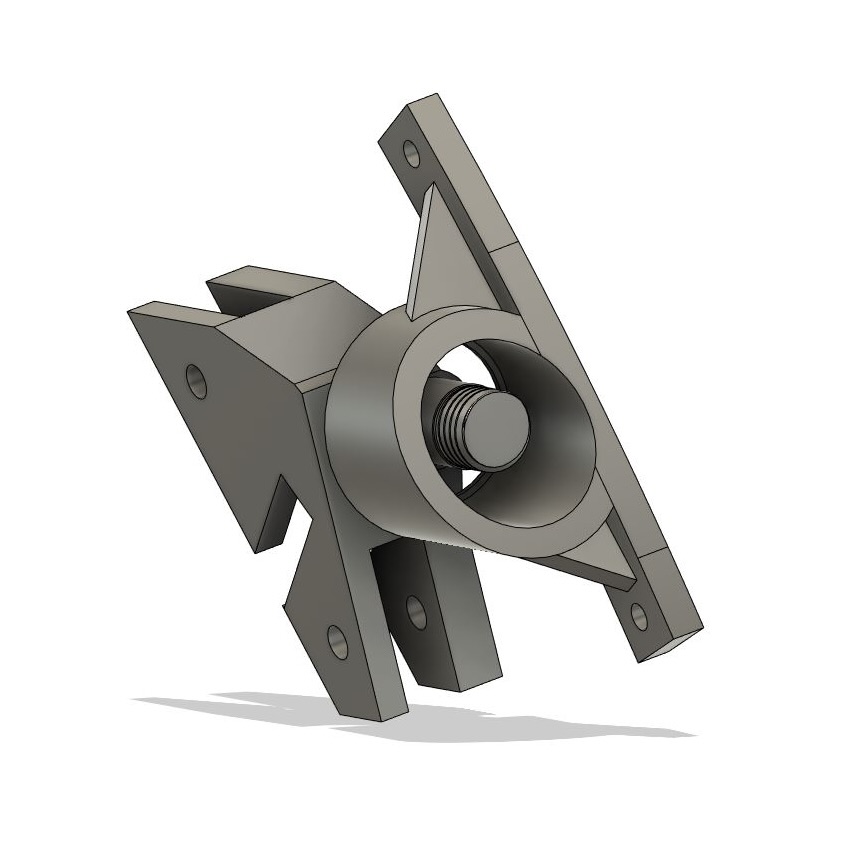

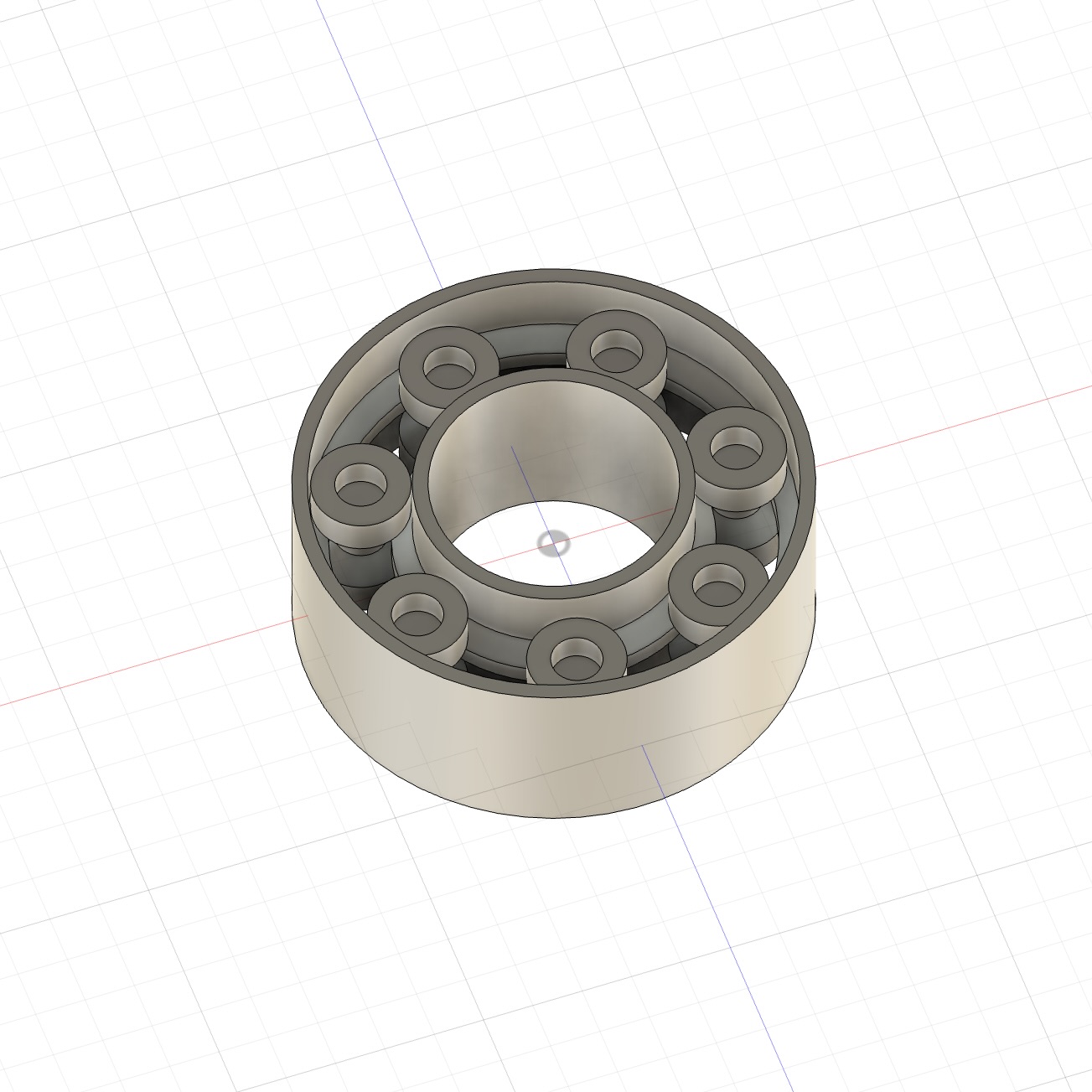

I designed a simple bearing-based mechanism for opening and closing the screen, which was 3D-printed along with self designed speaker mounts.

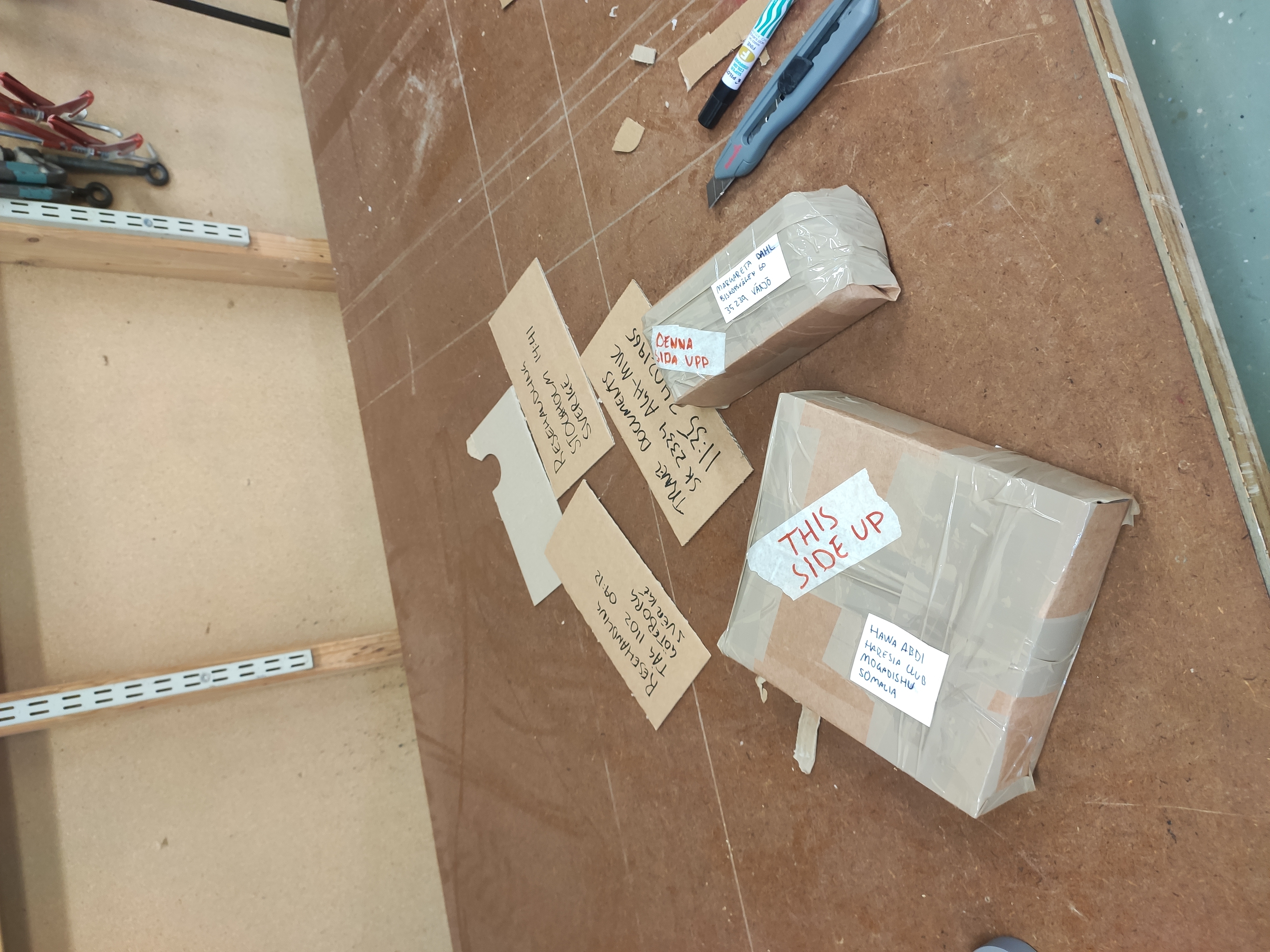

To finish the prototype, I sewed cushions for the seat and added a textile outer layer. The legs were painted and cables for audio and video were hidden.

The final prototype is a working mini dome cinema, a small, self-contained AV environment with a domed screen and a 12 speaker Dolby Atmos setup. The project showed what works well in this format and what needs refinement, especially in projection mapping and acoustic isolation. With better materials and budget, the concept can become a strong standalone installation.